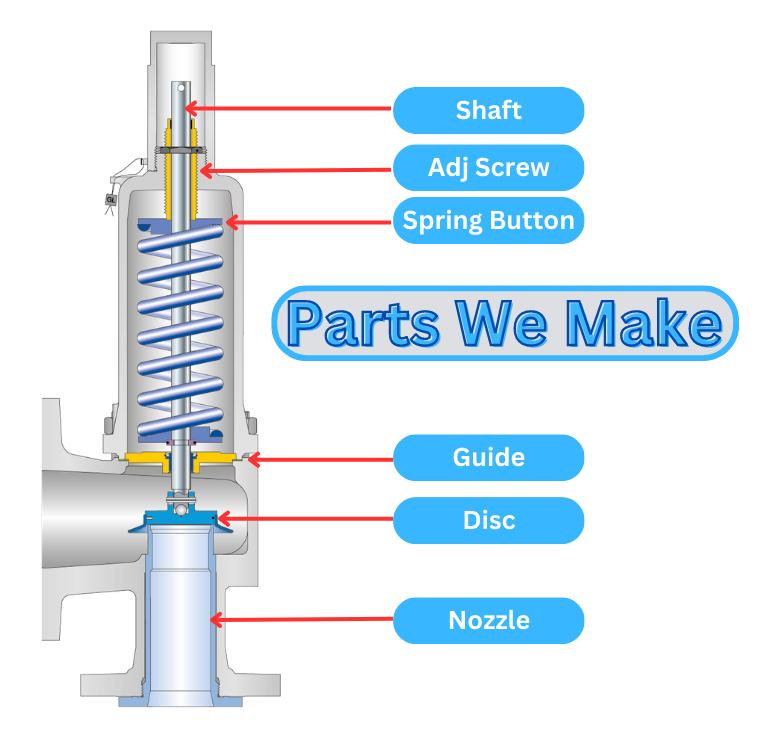

Valve Component Expertise

Components we make for

Pressure Relief Valves

Shafts

Adjustment Screws

Spring Buttons

Guides

Discs

Nozzles

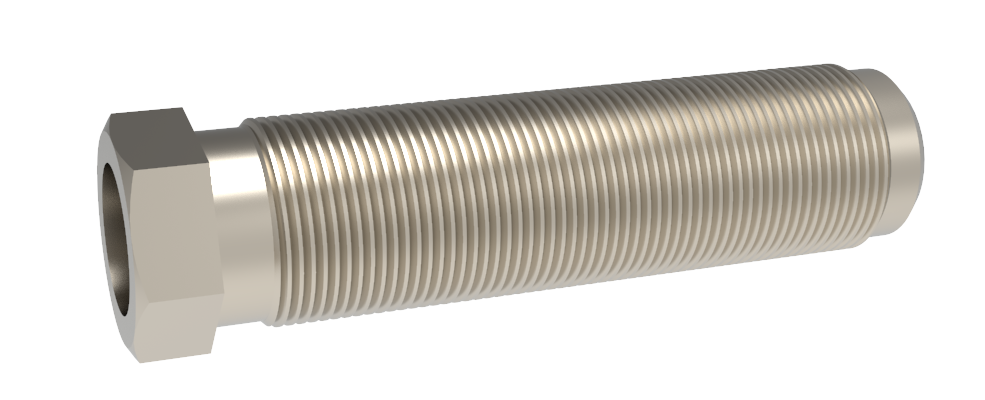

SHAFTS

Pressure release valves require core components which play a integral role critical to their funstionality. We’ve been a trusted source for these components since 1990

Material and Specifications

- Stainless steel

- Inconel

- 430F

- Monel

- .250″ up to 1.5″ Dia

- 2″-36 Length

- .002 Concentricity

- 32 Microfinish

- Sphericrical Radius

- Cross Drilled

- Threaded

- .002 Straightness

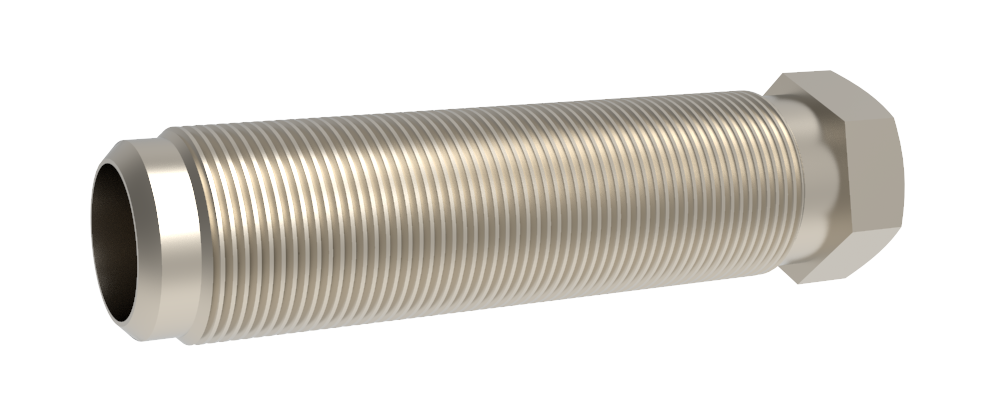

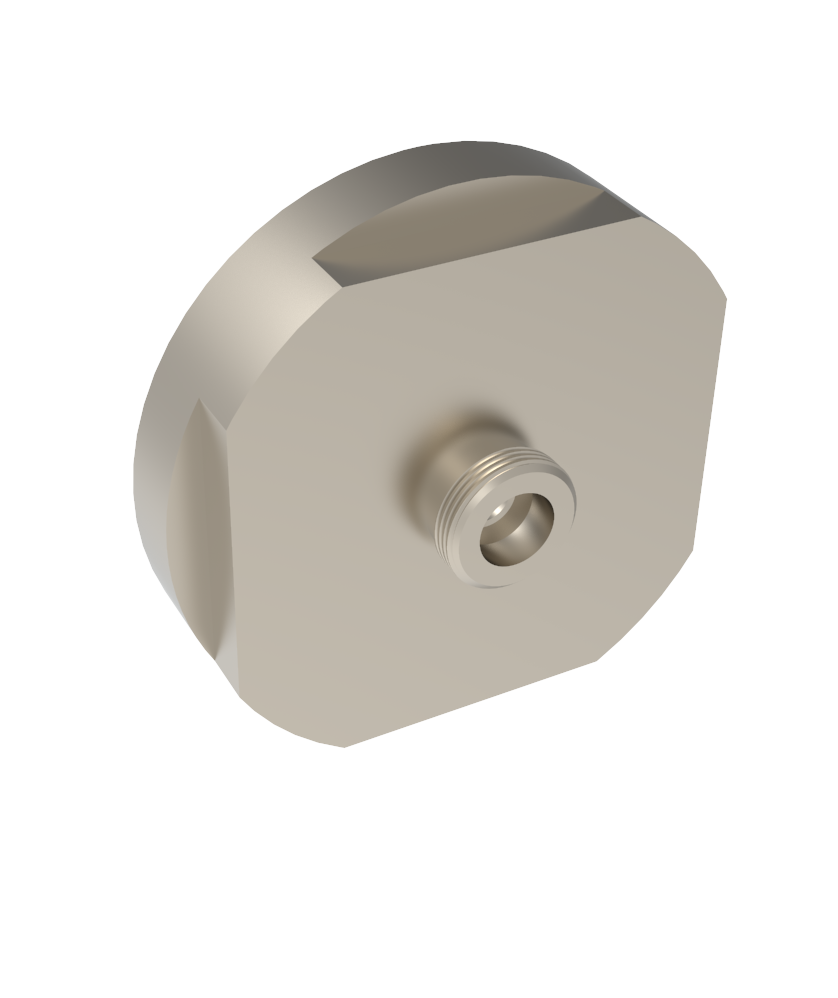

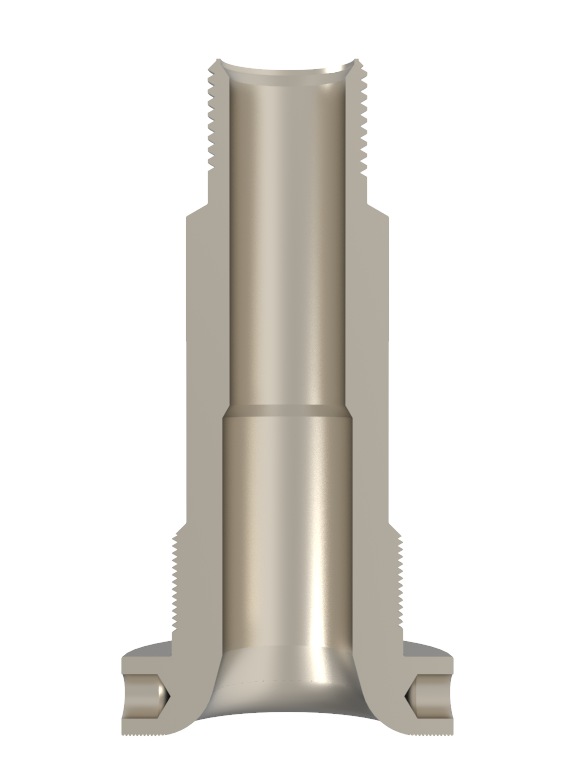

ADJUSTMENT SCREWS

Adjustment Screws are used to control the tension and pressure on spring release mechanics. We have the experience and expertise to offer a high value part consistently by a proven process.

Material and Specifications

- Stainless steel

- 17-4PH

- Heat Treated H1025 H1150

- Monel

- .750″ to 1.5″ Dia

- 2″-8″ Length

- .002 Concentricity

- 32 Microfinish

- Sphericrical Radius

- Hex

- Threaded

- .002 Straightness

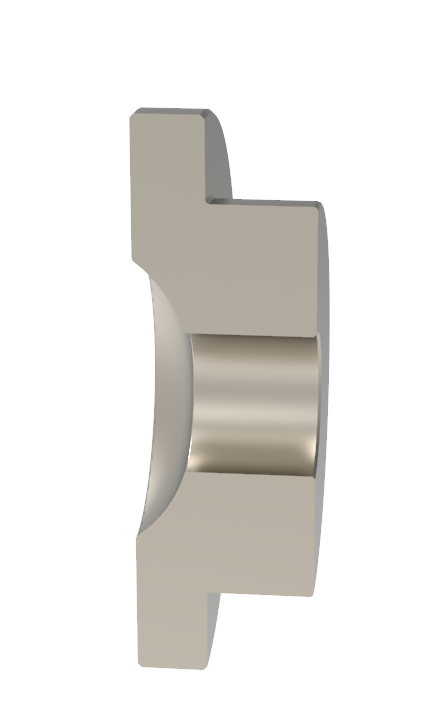

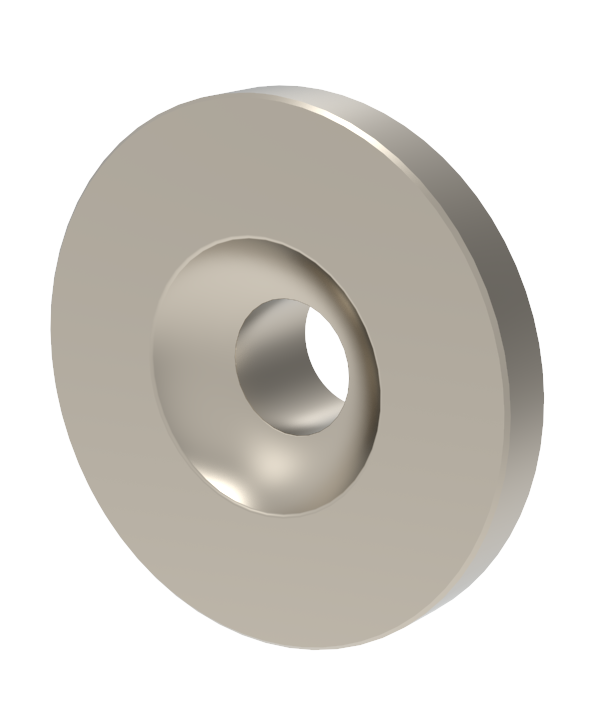

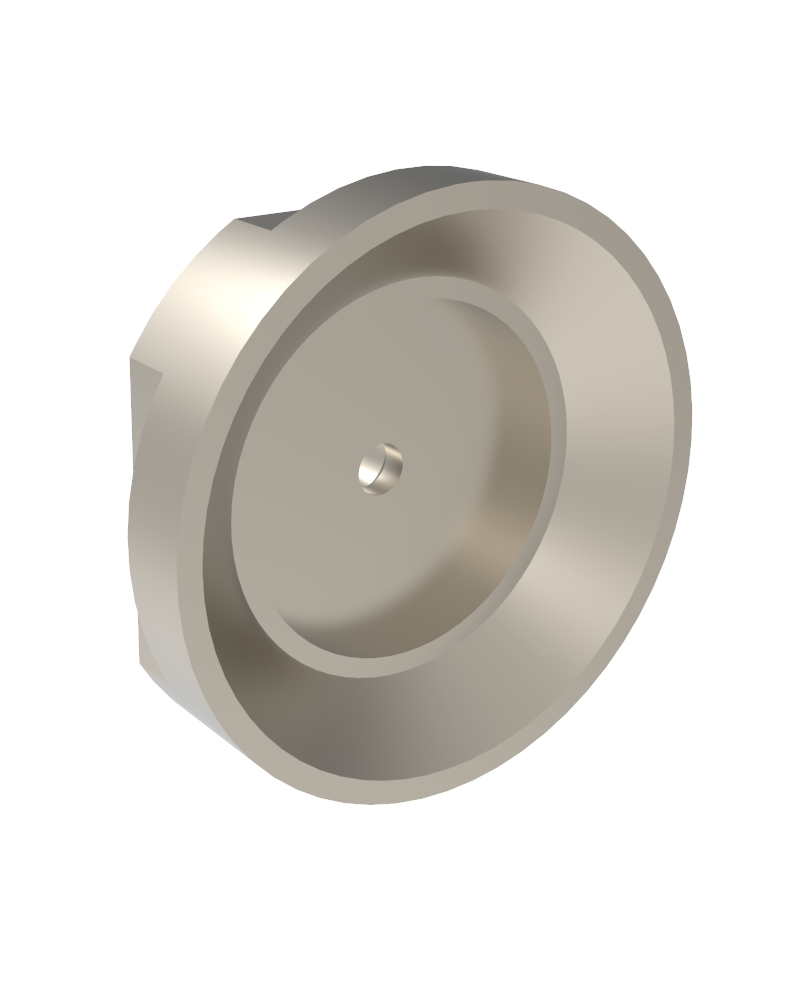

SPRING BUTTONS

Spring Buttons are used to control the tension and pressure on springs to keep downward pressure on the disc to seal the pressure realease valve. These are machined with efficiency through a proven process and inspected with lapped sperical ball for accuracy.

Material and Specifications

- Stainless steel

- 17-4PH

- Carbon Steel

- Monel

- .250″ to 6.0″ Dia

- .100″-2.0″ Length

- .002 Concentricity

- 32 Microfinish

- Sphericrical Radius

- Concave Radius

- Hardened as required

- .002 Straightness

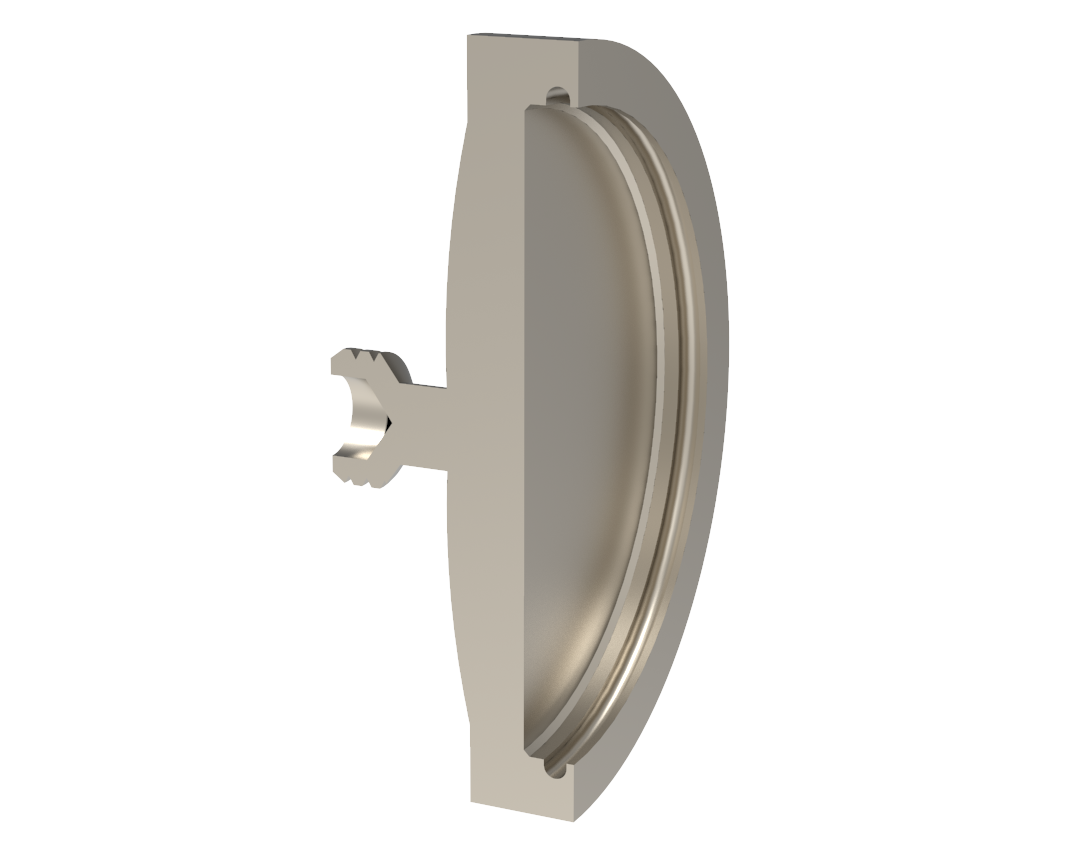

DISCS AND DISC HOLDERS

Discs and their respective disc holders seal the valve with under extreme pressure with precision. The dim tol of the mating radius is key to the funcionality of alignment and seating of disc precisely on the nozzle. We pay close attention to accuracy of a seal and the form of “O” Ring groove.

Material and Specifications:

- Stainless steel

- 17-4PH

- Heat Treated H1025 H1150

- Monel

- .5″ to 10″ Dia

- .25″-4″ Length

- .002 Concentricity

- 32 Microfinish

- Sphericrical Radius

- Broached Hex

- Precise Threaded

- .002 Radius Profile

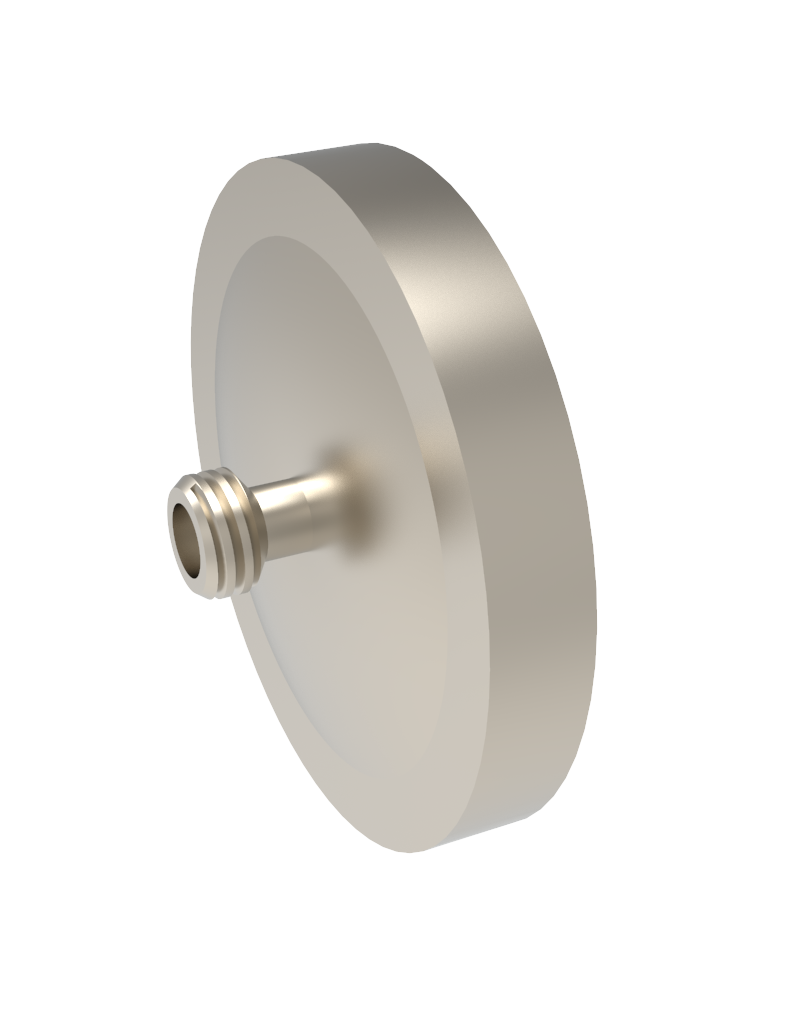

Nozzles

Nozzles seal against their respective disc and seal the valve with under extreme pressure with precision. The dim tol of the seat surface is key to the funcionality of alignment and seating of disc precisely on the nozzle. We machine the nozzle with .003R corners and +/-.001 tol.

Material and Specifications:

- Stainless steel

- 17-4PH

- Inlet radius

- Monel

- .5″ to 10″ Dia

- .25″-4″ Length

- .002 Concentricity

- 32 Microfinish

- Sphericrical Radius

- Spanner Wrench Holes

- Precise Threads

- .002 Radius Profile

Range of Precision Valve Compenents We Machine

We machine a wide array of components for the valve industry. We have proven processes and methods to ensure a precise part is machined to spec and shipped protecting critical to quality features. The exotic raw materials are used specifically for the pressure valve field because they can hold up in very harsh, intense environments, for example, the hight pressure of steam or a caustic, corrosive chemical application. These alloys need to be corrosion resistant, yet durable and strong enough to perform under pressure

Rehtek’s machine shop works with the following exotic materials;

- Inconel

- 4140

- Hastelloy

- Stainless steel

- Invar

- Hastelloy

- Monel

- Nickel

- 430F

- 440

- 321

- 17-4PH H1150